Precision In Practice

At Millwright, we focus on small batches, ensuring personalized attention and fostering professional expertise in CNC machining. Join us to hone your skills and become a proficient CNC professional.

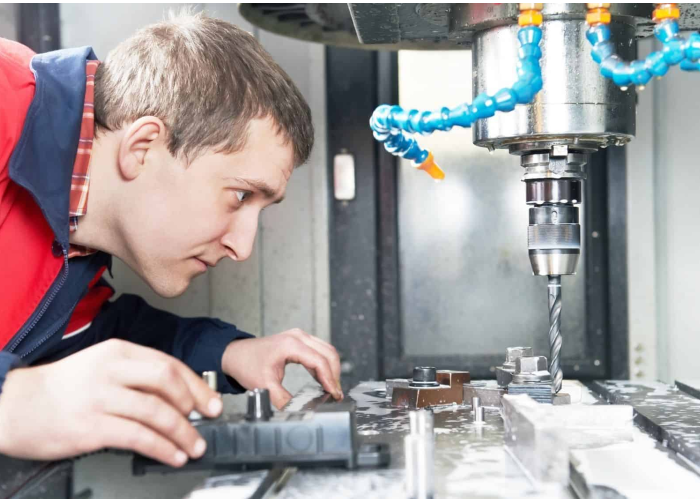

Welcome to Millwright's Hands-on training in CNC Machining, where we redefine CNC machining education with our hands-on approach and industry-leading expertise. With over 20 years of experience, our seasoned professionals are dedicated to providing you with practical skills that go beyond theoretical knowledge.

Get More Details

Safety and Best Practices

Safety protocols in a CNC shop, Maintenance and troubleshooting of CNC machines

Technical Drawings and CAD

Reading and interpreting technical drawings with basics of CAD software for CNC applications.

Tooling and Workholding

Types of cutting tools and their applications, Workholding techniques for various machining tasks.

Machine Setup and Operation

Setting up CNC machines for various operations.

CNC Programming

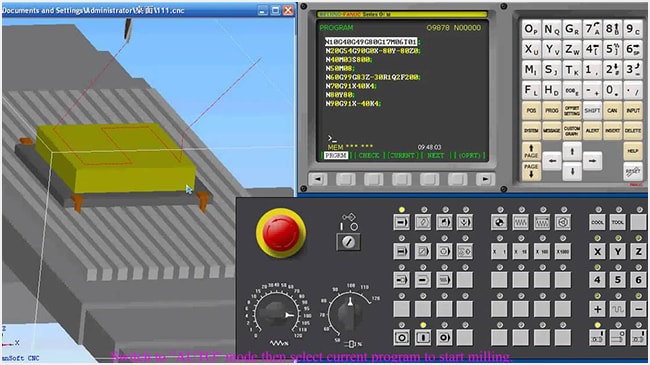

Introduction to G-code and M-code, Creating and editing CNC programs.

Our institute boasts a cutting-edge facility equipped with the latest CNC machinery, tools, and other instruments, ensuring excellence in hands-on training.

Measuring instruments and gauges tailored to enhance teaching on quality and precision.

At Millwright, we believe in learning by doing. That's why we offer 100% hands-on classes inside our modern machine shop. Our curriculum is carefully crafted to give you real-world experience in setting up, operating, and programming CNC machines.

At Millwright, we focus on small batches, ensuring personalized attention and fostering professional expertise in CNC machining. Join us to hone your skills and become a proficient CNC professional.

Pracital classes on Industrial VMC and CNC lathe Machines, Also individual project for every candidate to built more confidence on Interviews.

We understand that transitioning into the workforce can be daunting. That's why we offer job assistance support to help you find employment opportunities after completing our training programs. From resume writing to interview preparation, we're here to support you every step of the way.

Benefit from the guidance of instructors with over 20 years of industry experience in CNC machining training.

As a CAD/CAM/CNC consulting company with a team of well experienced experts in the area of CNC machining, We have a focused vision in providing Manufacturing solutions, CAD/CAM/CNC Training and CNC Programming Services for manufacturing industries in different verticals.

Our new batches commence on the first Monday of every month, providing regular opportunities for enrollment and ensuring consistent progression in our programs.

Each batch is limited to just six students, ensuring a focused and interactive learning environment. This small class size allows for personalized attention and maximizes hands-on learning opportunities in our efficient program

It's a one-month program, with five hours of instruction daily, six days a week

Yes, we Offer Job Placement Assistance Or Internships

History of CNC machines.

Advantages & Disadvantages of CNC

Types of CNC Machines

Major CNC machine Manufacturers

Mechanical basics

Electrical basics

Axis Direction

Types Spindle taper

Types of holders

Tool material selection & Characteristics

Types of tools

Types of operations

Types of clamps & fixtures

Machine Control Panel Operating (JOG Mode, MDI, Edit, Auto, Single block, etc.)

Work offset & tool offset on machines & software (Geometry offset, Wear offset.)

Engineering drawing reading & understanding

Process planning

Typical G codes & M codes

Absolute Coordinate & Incremental Coordinate

Feed, Speed & Tool change Commands

Basic Motion Commands with Examples

Program Structure

Cutting tools and Cutting parameters calculation.

Professional Programming with process planning sheet

Machining Operations from Bar stock

Sample Casting Models for Programming

Advantages of CAM software

Applying of tool paths

Check simulation for collisions & Proper tool movements.

Generating shop documentation & setup sheets

Generating NC codes

Cycle time calculation

Programming transfer using RS232 & Flash card.

We bring experienced industry professionals and mentors from different departments like Production, PED, HR, Technical Sales, and more to strengthen your career guidance, ensuring you gain valuable insights and achieve your goals.

20+ years of experience in CNC machining and providing consulting for the manufacturing industry

An Application Engineer with Hands-on experience in CNC machining and various CAD/CAM software

Seasoned Technical and Sales Expert with a rich history Die & Mold Industry,Cutting Tools, Machine Tools,CAD-CAM,

A seasoned engineer in production and running his own manufacturing industry to serve various other industries

A proficient engineer in the manufacturing industry, working as a manager in NPD at TVS group

Here I am well-trained For The course of Hands-on Training in CNC Machining and my confidence level improved. Teaching according to our mentality is very excellent and the software and systems also improved my knowledge. Their hospitality and Friendly sharing many things. Thanks to Millwright Team.

As I am a working professional it was hard to give constant time for training but thanks to the institute for their one-to-one training facility. Based on my timing they scheduled the classes & helped me to finish the classes without compromising with my working hours.

At the end of the training, we had an opportunity to work on a working CNC machine. During this training, we saw various tools and its types, various operations which are carried out on a regular basis. This training has proved very beneficial for me. I am studying in UK and I have an upper hand over others.

The faculty was very interactive & had relevant knowledge about the course. The hands-on session in machines helped me a lot to gain more practical knowledge & make me more confident in handling of CNC machines.Now I have the confidence to face interviews & now I am very much effective in myself.